Aluminium Fabrication Trends: What to Expect in the Future

WC

The Future of Aluminium Fabrication

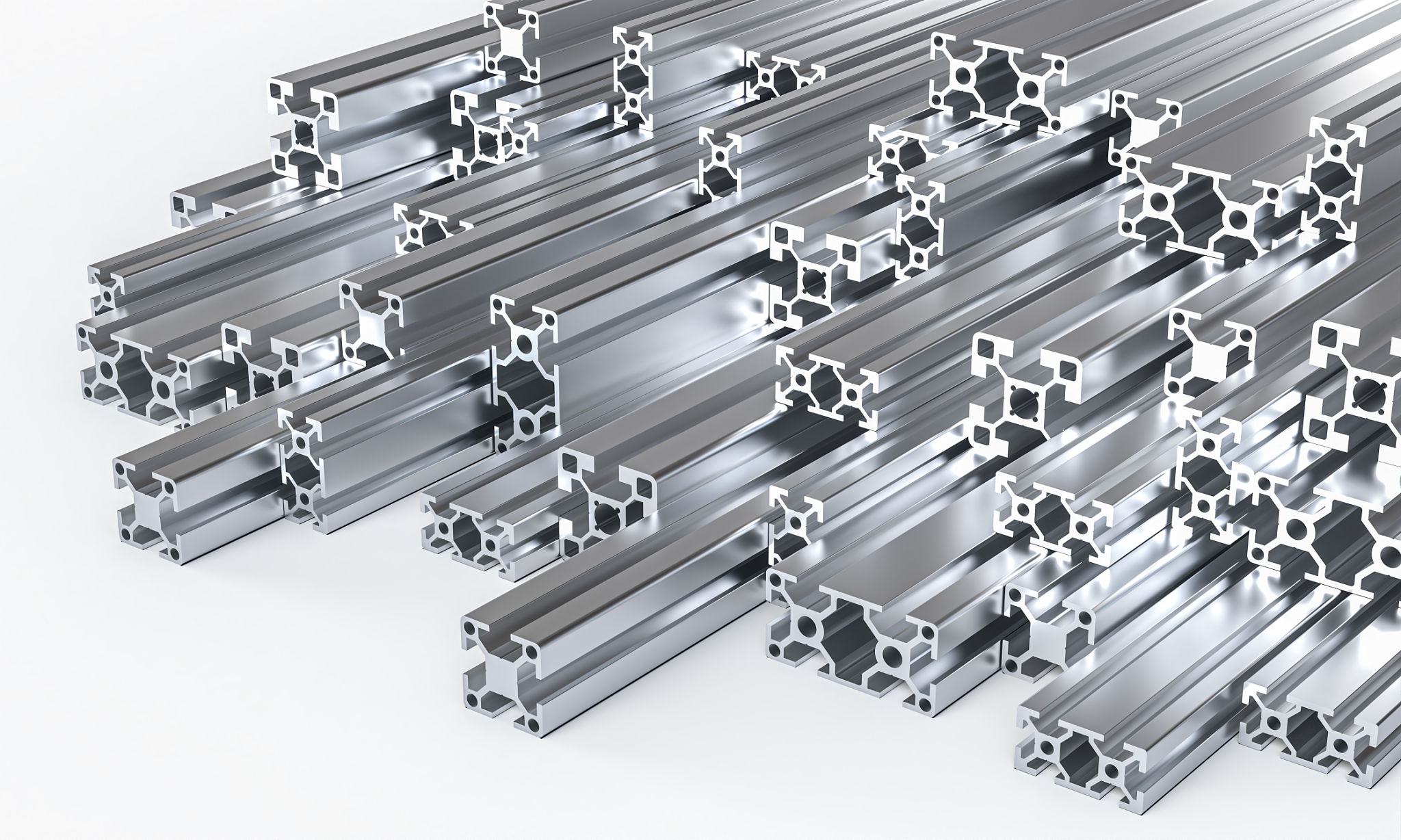

As the world evolves, so do the industries that support global infrastructure and manufacturing. Aluminium fabrication, a crucial component in many sectors, is no exception. Understanding future trends in this field is essential for businesses and professionals looking to stay ahead of the curve.

Aluminium's lightweight and durable nature makes it a popular choice in various applications, from construction to automotive manufacturing. As technology advances and environmental concerns grow, the methods and practices in aluminium fabrication are set to change significantly.

Embracing Technological Advancements

One of the most significant trends in aluminium fabrication is the integration of cutting-edge technology. Automation and robotics are becoming increasingly prevalent, streamlining production processes and enhancing precision. By adopting these technologies, companies can reduce human error, increase efficiency, and cut costs.

Additionally, advancements in computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allow for more complex and intricate designs. These tools enable fabricators to produce high-quality products with great accuracy, meeting the demands of modern industries.

Sustainability at the Forefront

The push for sustainability is reshaping industries worldwide, and aluminium fabrication is no exception. As environmental concerns take center stage, fabricators are focusing on reducing waste and improving energy efficiency. Recycling aluminium is becoming more critical than ever, as it requires only 5% of the energy needed to produce new aluminium from raw materials.

Moreover, sustainable practices not only benefit the environment but also offer cost savings. Companies that invest in green technologies can expect enhanced brand reputation and customer loyalty, as consumers increasingly prioritize eco-friendly products.

Customization and Personalization

With the rise of consumer demand for personalized products, aluminium fabricators are exploring new ways to offer customization options. The flexibility of aluminium allows for a wide range of finishes and treatments, enabling unique designs tailored to specific client needs.

Advancements in additive manufacturing, or 3D printing, also play a role in this trend. By utilizing 3D printing technology, fabricators can create intricate aluminium components with minimal material waste, offering a cost-effective solution for customized production.

Enhanced Safety Measures

Safety remains a top priority in aluminium fabrication. As production processes become more complex, ensuring the safety of workers is paramount. The future will likely see increased implementation of safety protocols and training programs to mitigate risks associated with advanced machinery and technology.

Companies investing in safety not only protect their workforce but also reduce downtime caused by accidents and injuries. This trend highlights the importance of fostering a safe working environment as part of overall business strategy.

Global Market Expansion

The global demand for aluminium is on the rise, driven by industries such as aerospace, automotive, and construction. As a result, aluminium fabricators are expanding their reach into international markets. This expansion offers opportunities for growth but also presents challenges associated with navigating diverse regulatory landscapes and cultural differences.

To succeed globally, companies must remain adaptable and responsive to changing market demands. Building strong partnerships and investing in local expertise are strategies that can help overcome potential hurdles in international expansion.

As these trends unfold, staying informed and prepared is crucial for those involved in aluminium fabrication. By embracing technological advancements, focusing on sustainability, offering customization, prioritizing safety, and expanding globally, businesses can ensure their success in this evolving industry.